How to Measure Expanded Metal Mesh

Expanded metal is used in a wide variety of industries due to its strength, versatility, and aesthetics. To ensure proper use, it is important to know how to accurately measure expanded metal. This guide will teach you the main dimensions of expanded metal and how to read the dimensions using tools such as digital calipers.

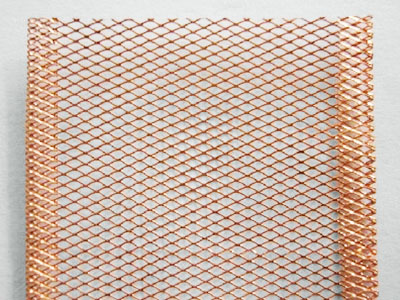

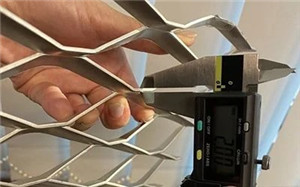

1. Thickness Measurement

The thickness of expanded metal refers to the original sheet metal's thickness before it is slit and stretched into mesh. This is a critical factor in determining the strength and load-bearing capacity of the mesh.

Tip: Use a digital caliper to measure the solid part of the strand to get the raw material thickness.

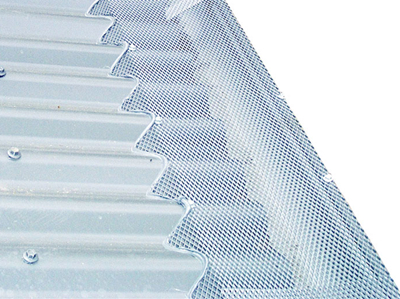

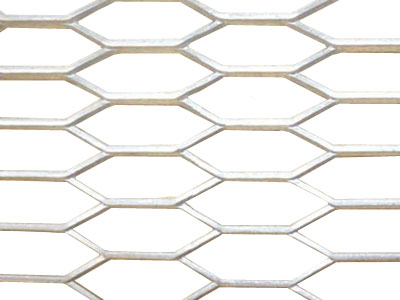

2. SW (Short Way of Diamond) Measurement

SW, or Short Way of the Diamond (SWD) refers to the shortest distance across the expanded metal mesh opening. It's typically measured horizontally from the center of one strand to the center of the next.

Tip: The SW dimension impacts the mesh’s flexibility and the size of the openings, which affects airflow and safety.

Example from image: The digital caliper shows an SW of 36.10 mm, measured across the narrow width of the diamond opening.

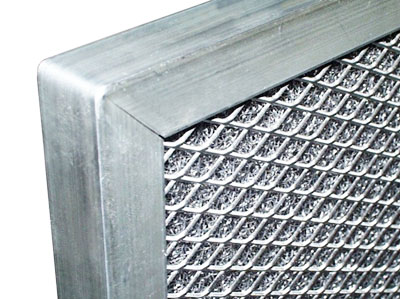

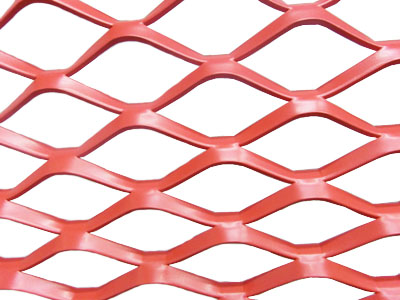

3. LW (Long Way of Diamond) Measurement

LW, or Long Way of the Diamond (LWD) is the longest length of the expanded metal diamond-shaped opening, usually measured vertically.

Tip: LW plays a major role in the strength and rigidity of the mesh. A longer LW allows more light or air to pass through but may reduce strength.

Example from image: The caliper shows an LW of 101.62 mm, which is the full length of one diamond opening.

4. Strand Width Measurement

The strand of expanded metal is the strip between the openings. The strand width determines the amount of metal remaining in the mesh and directly influences durability and weight.

How to measure: Use a caliper to measure the flat part of a strand (not including knuckles or raised areas).