comparison between expanded metal and perforated metal

Expanded metal and perforated metal are both commonly used in industrial, architectural, and functional applications, but they have key differences in their manufacturing processes, properties, and typical uses.

The table below summarizes the key difference of expanded metals and perforated metals

Item | Expanded metal | Perforated metal |

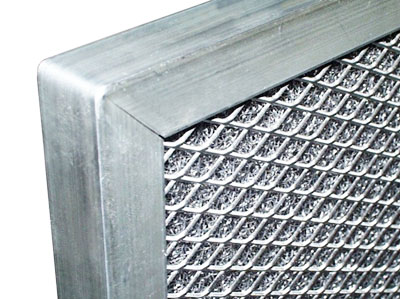

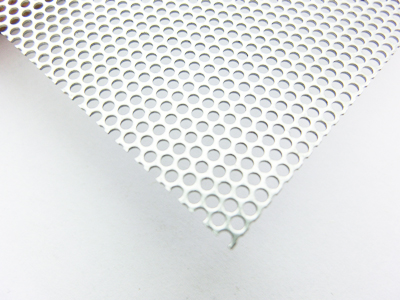

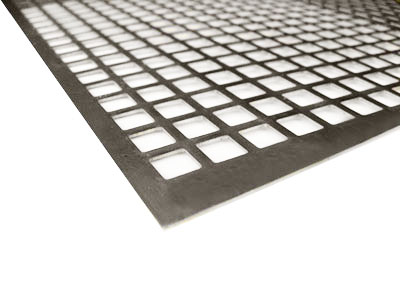

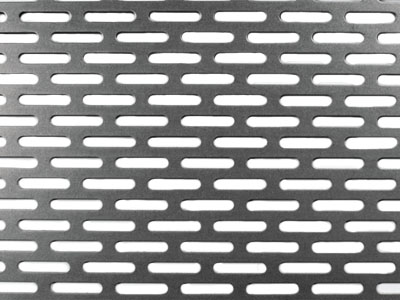

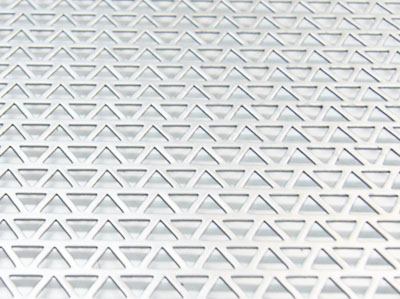

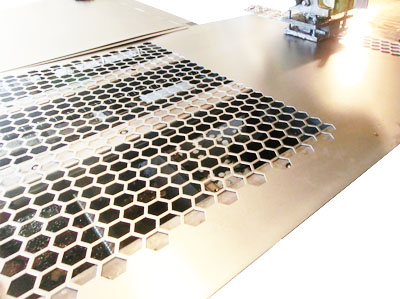

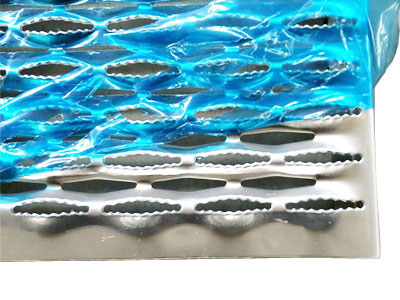

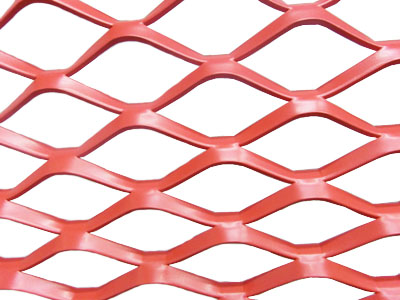

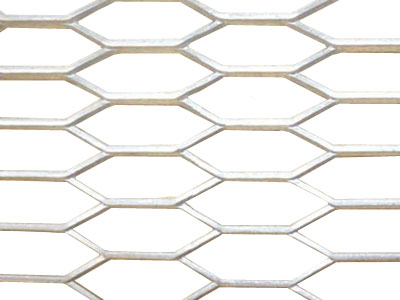

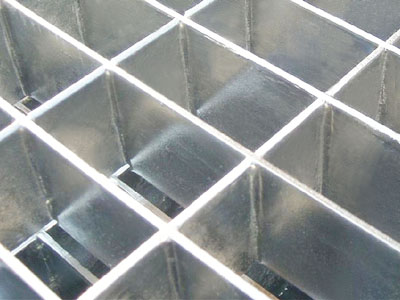

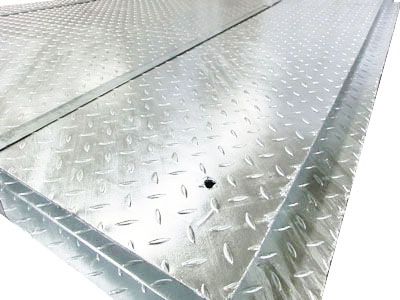

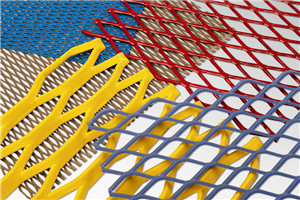

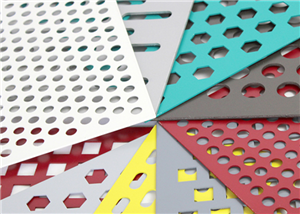

Manufacturing Process | Made by cutting and stretching a single metal sheet into a mesh-like pattern, forming diamond-shaped or other openings without generating any waste material. | Created by punching holes into a metal sheet in a predetermined pattern, which results in scrap material. |

Strength &Durability | Retains the original sheet's strength because no material is removed, providing a more rigid structure with high load-bearing capacity. | Slightly weaker than expanded metal of the same thickness because material is removed during the punching process, but it still offers significant durability. |

Weight | Lighter than the original solid sheet due to its open design, but may be heavier than perforated metal for the same open area percentage. | Weight depends on the percentage of material removed; it can be lighter than expanded metal if the holes are large and closely spaced. |

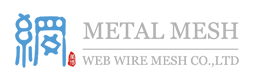

Aesthetics | Has a more industrial or textured look with three-dimensional appeal due to the raised areas from the stretching process. | Offers a cleaner, more uniform, and customizable look since hole size, shape, and pattern can be tailored to specific designs. |

Ventilation & Light Transmission | Allows good airflow and light transmission but with a slightly obstructed view due to its textured surface. | Provides better control over airflow, light transmission, and visibility, as hole size and pattern can be precisely determined. |

Cost and Waste | More cost-efficient in terms of material use since there is no waste in the manufacturing process. | May have higher material costs due to the scrap generated, though the scrap can often be recycled. |

Applications | Fencing, walkways, grates, and security screens due to its strength and durability. Architectural cladding and industrial applications where weight and ventilation are critical. | Acoustic panels, filters, enclosures, and decorative screens where aesthetics and precision are more important. Applications requiring specific airflow or drainage rates, such as HVAC systems or sieves. |